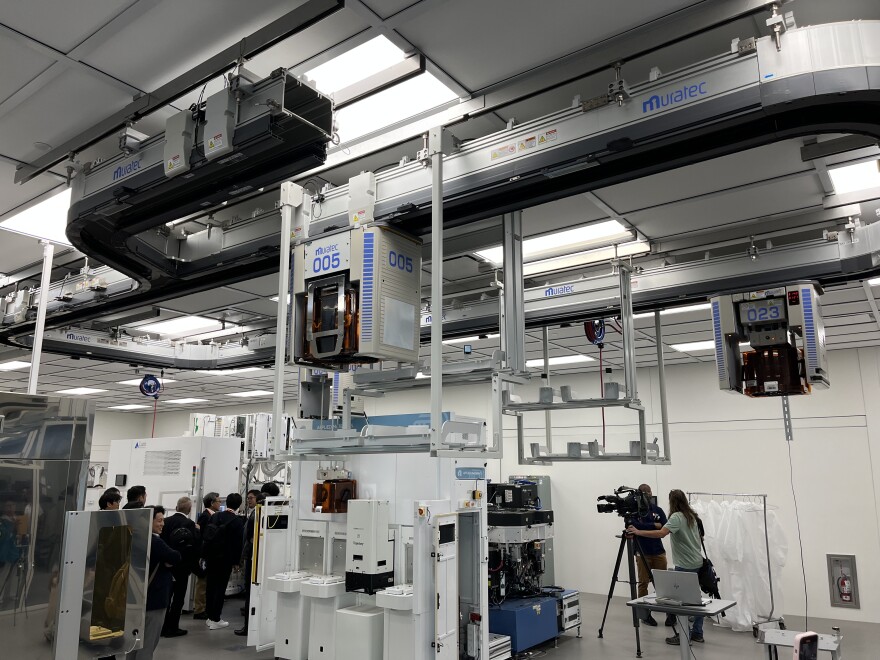

The recent opening of the Micron cleanroom simulation lab at Onondaga Community College makes it one of the few places outside of an actual research facility to give students the full material handling experience.

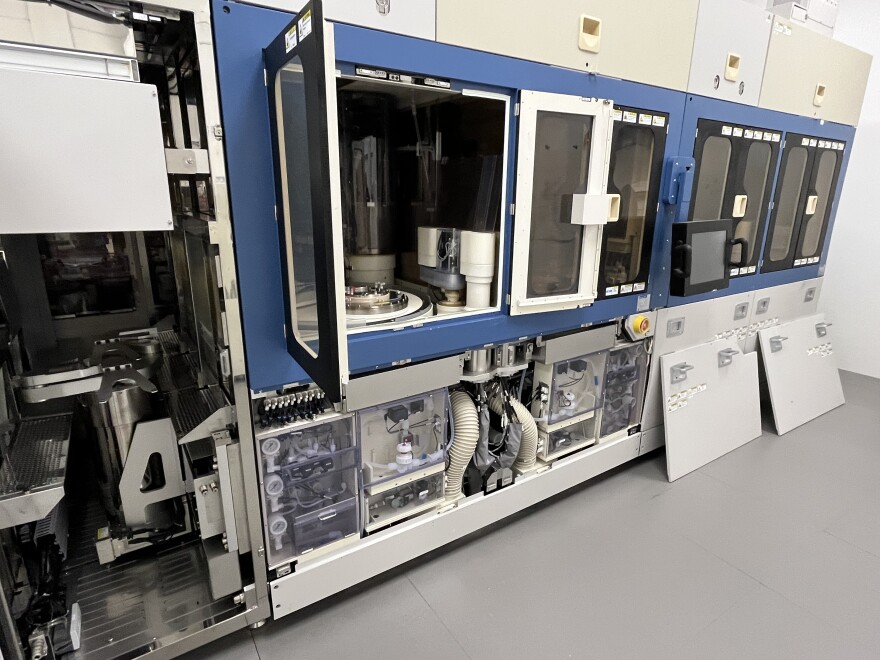

The machines in the 3,000 square foot, $15 million high-tech training ground perform a wide range of real-world functions. OCC Applied Engineering Professor Michael Grieb said students first go through some basics before diving into the machines, like suiting up with full protective gear as if they’re in a true cleanroom. Even the tiniest particles can do major damage in the chip fab manufacturing process.

“This equipment has a lot of electrical, mechanical, and fluid power solutions integrated with it,” he said. “And we're going to be injecting failure modes and different tasks for the students to go in there and either remove and replace, remove, diagnose, troubleshoot in various forms.”

Grieb said multiple classes will use the simulation lab throughout the semester.

OCC’s Facilities Project Manager Odae Badwan said the equipment is very specialized.

“A lot of this equipment nobody's ever seen before, so we had to work with a various number of vendors from all around the world,” he said. “They literally flew in from all around the country, the techs, to help us put this thing together.”

The machines came from Micron chip fabrication plants in Taiwan, Japan, Singapore, Idaho, and Virginia. Badwan said it’s critical to know who to talk to in order to keep the lab on the cutting edge.

“People keep telling me, will this ever be completed? I don't think it will ever. I think we'll always be advancing,” he said. “We’ll always be looking for the latest and greatest and we'll take any donations that any of these vendors are willing to give us.”

Inside the cleanroom, it’s hard not to notice the persistent electronic carnival music from one of the machines. Badwan said it’s a safety feature.

“So that music comes whenever there's an error,” he said. “So essentially, it's not fully programmed yet. So that music is just letting you know that it's moving.”

Sensors stop the machine and sound an alarm if someone or something gets in the way.

More than 300 students are enrolled in semiconductor programs at OCC, and they’re among those who get real-world experience inside the cleanroom simulation lab.